Phidix 3000lb Pull-Only Brake Control Cable: Industrial Strength, Engineered Precision

When your system demands control under tension—without compromise—the Phidix 3000lb pull-only brake cable delivers mechanical actuation built for rugged duty cycles and high-force reliability.

Developed for environments where electronics fail, hydraulics complicate, and failure isn’t an option, this cable is trusted across industries that require dependable, direct mechanical control.

Whether it’s a mining lockout, construction park brake, offshore disconnect, or factory safety system—Phidix cables pull their weight.

Built for Heavy-Duty Mechanical Actuation

Ideal Applications:

• Construction Equipment Braking: Earthmovers, wheel loaders, and trenchers with manual or redundant brake systems

• Mining & Aggregate Systems: Emergency lockouts, chute gates, or cable winch actuation

• Offshore & Marine Gear: Control of PTOs, hatches, or manual overrides where corrosion resistance matters

• Material Handling Machinery: Crane interlocks, conveyor tensioners, and lift-arm mechanical brakes

• Rail, Utility, and Industrial Lockout Systems: Emergency disconnect and cable-actuated latching

In each case, high tensile strength and environmental durability are non-negotiable.

Key Mechanical Specifications

• Ultimate Tensile Capacity: 3000 lb (pull-only direction)

• Minimum Bend Radius: 7"

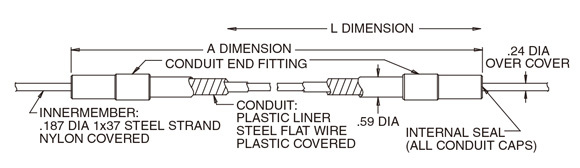

• Innermember: 0.187" dia, 1×37 galvanized steel, nylon coated

• Conduit System: Plastic liner + steel flat wire wrap + abrasion-resistant outer jacket

• Standard Travel Range: 2" to 6" (custom available)

• Service Environment: Vibration, corrosion, heat, and contamination resistant

What Sets It Apart

• Multi-Strand Inner Core: Uniform load transfer, fatigue-resistant, minimal stretch

• Sealed Conduit Ends: Prevents ingress of water, oil, dirt—ideal for field equipment

• Pcision-Lined Jacket: Reduces friction for smoother actuation and longer wear life

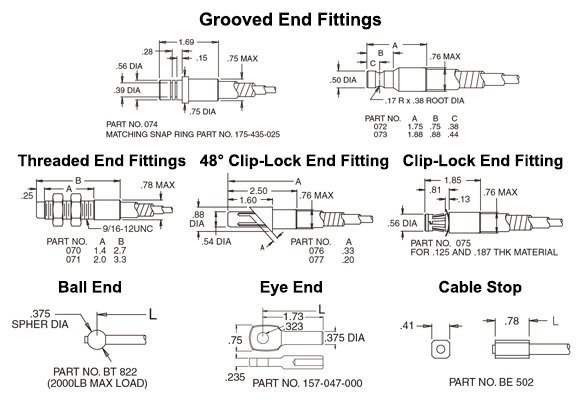

• Configurable End Fittings: Clevis, threaded rod, stop ends, ball/socket for diverse system layouts

When operating in demanding industrial systems, the ability to trust each pull cycle is what defines performance—and safety.

Engineering Support for Integration

Phidix offers full design and configuration assistance, including:

• Custom Lengths: Tailored A and L dimensions for tight envelope routing

• CAD Drawings: Provided for bracket and clamp planning

• Termination Matching: Support for clevis mount, bulkhead, and pivoting joints

• Test Data: Cycle life validation, salt spray performance, tensile compliance

Compared to 1500 Series

| Feature | 1500 Series | 3000 Series |

| Max Load | 1500lb | 3000lb |

| Bend Radius | 5" | 7" |

| Core Size | 1*19 | 1*37 |

| Use Case | Light-duty, compact installs | Heavy-duty, high-load mechanical systems |

| Flexibility | Higher | Lower, stiffer for load stability |

Choose the 3000 series when pulling strength and reliability override flexibility.

Common Misconceptions

Q: Is this just a scaled-up version of a push-pull cable?

A: No. It’s a single-direction, pull-optimized cable with reinforced core and jacket built for tension loads only.

Q: Will it perform outdoors or on mobile platforms?

A: Yes. Conduit structure and sealing were designed for exposed installation, including water, salt, and thermal cycling.

Q: How does it compare to hydraulic actuation?

A: It provides passive, manual control—no fluid circuit, no power, no delay—perfect for backup or primary mechanical systems.

Ready to Specify or Configure?

Reach out for:

• Application consultation

• CAD file access

• Lead time and MOQ estimates

Request 3000 Series Quote

Product Tags:

|

|

3000Lb Wire Harness Cable Assembly Pull Brake Control Cable Carbon Steel Images

|